|

|

|

|

|

|

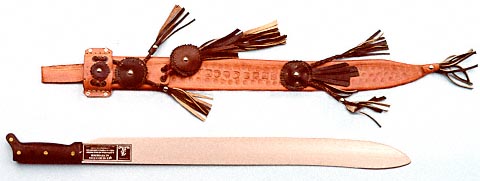

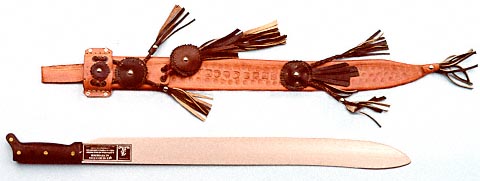

The machete as we know it today appears in many forms and shapes and goes by different names in the English speaking areas of colonization in Africa and the Far East than it does in America. According to the Oxford English Dictionary, the primary term is matchet, and the American term is machete, which is the same as the Spanish, which is the original tongue of the word. Some confusion has arisen because both are pronounced identically except for the final e, the t being silent. Though the form of the machete is of the simplest design, being three pieces only: two scales and a blade with integral tang, there can be found more elaborately decorated forms, especially of modern make, intended for the tourist trade and made in Latin America. When the machete first spread over the world by the sea trade, the major centers of production were in Collinsville, Connecticut, USA and in England, Germany, and later Czechoslovakia.

The use of the term machete in Spain is also applied to cutting implements of diverse sizes and purposes from quasi-swords designated in some areas as cutachas to short bayonet-like complex sidearms used by artillery men for clearing gun positions and for close-in defense before the age of rapid firing handguns.

The true machete as used for clearing land and for agricultural purposes may take form and size from 12 inches (machete cañero) to almost a yard, though most field machetes (machete de monte) range from 18 to 26 inches. It requires a mighty arm to swing a machete longer than 22 inches all day in the heat.

The machete, as used in America, was developed from the primitive whacking sticks used by natives to beat through the bush; some trace the design influence to the sailors' cutlass or the Californios' espada de ancha, though both of those are definitely weapons and are much more complex and much more expensive to make. A tool simply does not need a guard and or basket hilt. A definition as used in both English and Spanish dictionaries, a large knife used in Latin America (cuchillo grande), is closest to the truth. The form of large working machetes is simply that of butcher knives (c.f. The famous Russell Green River knives) enlarged fourfold.

The machete as used in the jungles of America is entirely distinct in its method of wielding from the edged weapons of Europe, swords, cutlasses, and sabers, which are held with the whole hand and all the fingers in what may be called the thrusting grip or the hammer grip depending on whether the wrist is dropped or not, so that the line of the weapon is either at right angles or in line with the axis of the lower arm. The machete is, instead, held loosely between the thumb and first finger and allowed to pivot in the hand through a large arc, thus slicing its way through the soft, herbaceous vegetation common in the American tropics and that of the Pacific Islands. Deep in the tropical jungles of the Amazon basin, the machete is the only modern implement found in the camps of otherwise Stone Age Indio cultures.

Compare the machete with the native tools of jungly South East Asia, and the Indonesian archipelago, where the tool-weapons such as the parang, the golok, bolo, and barong are wielded with a full hand chopping grip which is needed to cut through the woody vegetation of that area. The nortemericano and his European ancestors used axes instead of one-handed tools for heavy cutting.

|

|

|

Although there was iron smelting and metalworking in shops and ateliers before the eighteenth century, until the invention of steam power - a source independent of the pull of gravity (water power) - there was no way for development of the massive smoke and fire belching iron and steel processing works which dominated modern industrial production until recent years. Even as late as the 1960s when the electric furnace had superseded the open hearth, blast furnaces, and Bessemers of the nineteenth century, nations were building steel plants as a symbol of their arrival into modern industrial society, ignoring the interdependence of the world economy.

Once steel became a relatively cheap commodity, it made possible the making of rolled rails, which led to the transportation developments of the nineteenth century, just as the use of sheet steel facilitated the automobile age of the twentieth. It then became cheap enough to make cutlery, edged tools, and striking tools completely of steel. Prior to the 1820s, the use of steel bits inset into iron heads was the common method of crafting such items. As to common butcher knives and other similar forged items, they were still at that time being beaten out by hand, one at a time by smiths.

Though specialization of labor had long since taken place in the cutlery and firearms industries, individual arms essentially were unique pieces until the American system of manufactures (interchangeable parts) was introduced, first into arms making. Steam power also facilitated the introduction of power hammers, forging machines, grinders, cutters, etc., eliminating most of the "Armstrong" methods of antiquity.

The introduction of "cast steel" or acero fino in Spanish, in quantities cheap enough to make inexpensive industrial and agricultural tools such as cane knives, machetes, axes, and adzes, as well as striking tools, came about in the early nineteenth century after development of large integrated steel mills began.

The term of "cast steel", as stamped on products of the Collins Company, did not mean it was actually cast, but that it was of comparable flawless quality to the steel previously made in small amounts for welding into the heads of axes to form the bits. After all, one could not have afforded to make of expensive steel, an item which by the end of the nineteenth century and up till the 1940s, sold in most foreign markets after transport for less than a Yankee dollar apiece in the form of the common machete de monte or field machete. And there were all sorts of other edged tools that became marketable on a national or world wide basis when good steel became cheap. Finally the development of rolling mills allowed the production of consistent sheet and bar stock perfectly suited to making thin, flexible blades capable of holding a razor edge.

The classic Collins machetes as made in Connecticut were made by forging. Collins, whose business began in the 1820s, when they built their overseas plants in the 1950s, began to use stock removal (punching out from steel plate with dies and then reducing by flat grinding and planers) when it became the norm. Only by the use of automation can a manufacturer afford to pay a worker American wages to make such simple items. And probably the military's buy American rules have had a lot of influence on keeping any manufacture in the US. Today the only major domestic maker left, Ontario, uses the stock removal method.

The machete as we norteamericanos usually think of it unfortunately has a bad press - it seems it is only is worthy of mention when some maniac commits a "machete murder" or some Africans chop up their ethnic rivals, or someone wildly waves one as a symbol of defiance. The most recent use (July 1999) I noticed in the papers was when, as the Coast Guard attempted to intercept a boatload of refugees from Cuba, one of the passengers waved a machete at the US crew. What was he thinking? The Anglo-American attitude is due partly to the lack of the use of machetes as everyday tools in Anglo-America. Even the common corn knife once so widely used in our society would scare most of the members of our urban dwelling society. How many of us have even visited a farm, let alone worked on one? We are several generations out of the back woods, most of us. But, as with so many ethnic tools, such as bill hooks and pikes, the machete has often found use in war as well as civil life, and thus is confused in the common mind with a weapon. And is often used so, unfortunately.

The common image of those in lands where machetes and their relatives find constant use is that of back-breaking sweaty labor--chopping corn, cutting cane, clearing jungle paths and fields. The machete is truly a common implement, in the sense that it is the implement of the common man, the campesino who does the work on the plantation, the hacienda, and the ranchero. These folks do not sit around the plaza in the evening singing such ditties as My Adobe Hacienda! The machete, tool of the commoner, is never found in the hand of the educated, the effete, or the overseer. Instead, they are the ones who wore the small swords, and, later, the cutachas, in this century more as a symbol of status than as true weapons.

Crude and simple as most machetes are, their form could not have been developed in the age before the wide use of steel bar and plate for manufacture of industrial age products. So the simplest most common agricultural tool imaginable is a pure child of the modern industrial age. Truly form does follow function in this case.